On October 17 Mitsubishi Heavy Industries Marine Machinery & Engine Co., Ltd., a wholly owned subsidiary of Mitsubishi Heavy Industries, Ltd. (MHI), unveiled the development of an electro-assist MET turbocharger saving approximately 30% electric power consumption compared to existing auxiliary blowers at MHI's Nagasaki Shipyard & Machinery Works. It was developed using a high-speed motor supplied by its partner, Calnetix Technologies (Calnetix), and is the result of collaboration between the two companies.

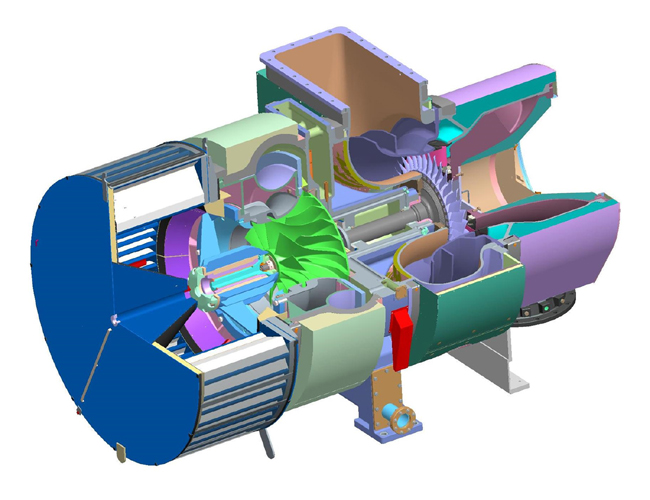

On October 17 Mitsubishi Heavy Industries Marine Machinery & Engine Co., Ltd., a wholly owned subsidiary of Mitsubishi Heavy Industries, Ltd. (MHI), unveiled the development of an electro-assist MET turbocharger saving approximately 30% electric power consumption compared to existing auxiliary blowers at MHI's Nagasaki Shipyard & Machinery Works. It was developed using a high-speed motor supplied by its partner, Calnetix Technologies (Calnetix), and is the result of collaboration between the two companies.The electro-assist MET turbocharger is a turbocharger that incorporates a compact electric motor limited to power functions that assists the driving of the hybrid turbocharger*. This provides optimization of plant efficiency when a ship is operating under slow steaming, improving the fuel combustion efficiency of the main engine, and enabling the same or better performance than an auxiliary blower while consuming little power.

The unveiling ceremony held at the Nagasaki Shipyard & Machinery Works was attended by around 70

customers from various fields, such as domestic shipping companies, ship owners and shipyards. Calnetix Co-founder and CEO Vatche Artinian, and Mitsubishi Heavy Industries Marine Machinery & Engine President Kazuo Soma also attended. The Company's VTI turbocharger that is variable nozzle turbocharger effective at low load, the first mass-produced model of MET-48MB with an optimal frame size for handysize bulk carriers, and Calnetix's 125kW binary generator (ORC module) for low-temp heat sources were on display at the venue.

customers from various fields, such as domestic shipping companies, ship owners and shipyards. Calnetix Co-founder and CEO Vatche Artinian, and Mitsubishi Heavy Industries Marine Machinery & Engine President Kazuo Soma also attended. The Company's VTI turbocharger that is variable nozzle turbocharger effective at low load, the first mass-produced model of MET-48MB with an optimal frame size for handysize bulk carriers, and Calnetix's 125kW binary generator (ORC module) for low-temp heat sources were on display at the venue."Like the hybrid MET turbocharger, the electro-assist MET turbocharger was created through collaboration between companies possessing advanced technologies. By combining the technologies of Mitsubishi Heavy Industries Marine Machinery & Engine and Calnetix, we completed a product that provides high energy efficiency and a reduced burden on the environment," Kazuo Soma said, highlighting the fact that the product utilizes the strengths of both companies.

Vatche Artinian made the following comment for a deep appreciation of the electro-assist MET turbocharger: "We are working with Mitsubishi Heavy Industries Marine Machinery & Engine to develop energy recovery systems that enable shipping companies to reduce operating costs by obtaining more energy from less fuel while remaining compliance with international rules and regulations concerning the marine environment. Like normal MET turbochargers, electro-assist MET turbochargers and hybrid MET turbochargers have a long product lifetime and can be installed without making significant changes to engines and offer excellent maintenance access, while being extremely compact devices that enable the best performance to be obtained when installed on a ship."

Mitsubishi Heavy Industries Marine Machinery & Engine and Calnetix have created innovative products that improve the energy efficiency of ships, including low-cost, high-efficiency heat recovery systems, such as Mitsubishi Heavy Industries Marine Machinery & Engine's hybrid MET turbochargers, for which Calnetix supplies high-speed generators. The two companies will continue to maintain their good relationship while expanding the framework for working together.

* Hybrid MET turbochargers incorporate high-speed generators, and utilize the energy generated by engine exhaust gas to provide up to 5% of main engine output. Because of this, hybrid MET turbochargers are able to provide electric power to the ship, and make it possible to significantly reduce ship fuel consumption by operating without auxiliary diesel power generation.